how to test machine coolant with a refractometer|refractometer conversion chart for coolant : exporter Refractometers for Metalworking Fluids (Coolant) - hand-held optical brix-based refractometer to measure coolant concentration Calibration is easy. Mix a small batch with a measuring cup and test it to see what the refractometer reads. The basic principle of steam sterilization, as accomplished in an autoclave, is to expose eac.

{plog:ftitle_list}

Autoclave validation ensures that sterilization processes in pharmaceutical, life sciences, and other regulated industries comply with regulatory requirements. Below, I will cover the regulatory requirements and uses of autoclaves and .

TEST your coolant. Using a dropper, extract coolant from your machine. Again using the dropper, place 2–3 drops of coolant onto the prism of the refractometer and carefully secure its cover plate. Make sure there are no dry spots or air bubbles beneath the cover . Refractometers for Metalworking Fluids (Coolant) - hand-held optical brix-based .

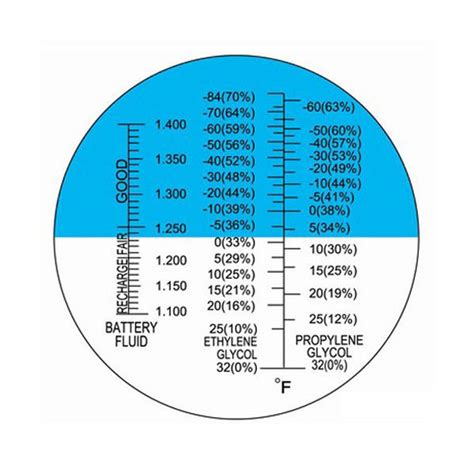

refractometer reading chart

TEST your coolant. Using a dropper, extract coolant from your machine. Again using the dropper, place 2–3 drops of coolant onto the prism of the refractometer and carefully secure its cover plate. Make sure there are no dry spots or .

Refractometers for Metalworking Fluids (Coolant) - hand-held optical brix-based refractometer to measure coolant concentration Calibration is easy. Mix a small batch with a measuring cup and test it to see what the refractometer reads. Coolants must operate within a specific concentration window to maintain the right amount of lubricity and additive content. Refractometers are instruments used to obtain a °Brix reading, which measures the oil content present in a coolant mixture.To test coolant with a refractometer, follow these steps: Extract coolant or fluid from your machine using a dropper. Place 2–3 drops of coolant onto the prism of the refractometer and secure its cover plate.

Here is a video of how to properly check coolant concentration using a refractometer. We have partnered with Eastern Oil Company to provide a free 5 gallon b.There are two handheld refractometers for use on the shop floor: analog and digital. Most maintenance personnel and machinists are familiar with the analog refractometers: flip-up lens cover, add a drop of coolant, close the lens cover, look through the eyepiece and read the scale.Using a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface. 54. 6.9K views 7 years ago. Lesson objectives include interpretation of a coolant manufacturer datasheet, concentrate proportions and measurement, mixing technique, sampling, and measuring the.

Maintaining the proper concentration of coolant is essential to ensure consistent machining performance and to prolong the life of the machine and its tools. In this guide, we’ll explain how CNC coolant refractometers work, as well as . A refractometer is an essential tool for accurately measuring the concentration of your coolant mixture. Here’s how to use it: Calibrate the Refractometer: Before taking any measurements, calibrate your refractometer using distilled water.

TEST your coolant. Using a dropper, extract coolant from your machine. Again using the dropper, place 2–3 drops of coolant onto the prism of the refractometer and carefully secure its cover plate. Make sure there are no dry spots or . Refractometers for Metalworking Fluids (Coolant) - hand-held optical brix-based refractometer to measure coolant concentration Calibration is easy. Mix a small batch with a measuring cup and test it to see what the refractometer reads. Coolants must operate within a specific concentration window to maintain the right amount of lubricity and additive content. Refractometers are instruments used to obtain a °Brix reading, which measures the oil content present in a coolant mixture.To test coolant with a refractometer, follow these steps: Extract coolant or fluid from your machine using a dropper. Place 2–3 drops of coolant onto the prism of the refractometer and secure its cover plate.

Here is a video of how to properly check coolant concentration using a refractometer. We have partnered with Eastern Oil Company to provide a free 5 gallon b.There are two handheld refractometers for use on the shop floor: analog and digital. Most maintenance personnel and machinists are familiar with the analog refractometers: flip-up lens cover, add a drop of coolant, close the lens cover, look through the eyepiece and read the scale.

Using a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface.

54. 6.9K views 7 years ago. Lesson objectives include interpretation of a coolant manufacturer datasheet, concentrate proportions and measurement, mixing technique, sampling, and measuring the. Maintaining the proper concentration of coolant is essential to ensure consistent machining performance and to prolong the life of the machine and its tools. In this guide, we’ll explain how CNC coolant refractometers work, as well as .

refractometer for coolant concentration

refractometer conversion chart for coolant

is graduated pipette more accurate than volumetric

is graduated pipette qualitative

is it easy hard for the elderly to use pipettes

Autoclave is used for the applications requiring constant pressure and temperature for long period of time. The majority of autoclave function is a use of heat and maintaining a temperature constant for complete sterilization.

how to test machine coolant with a refractometer|refractometer conversion chart for coolant